- +91 8123115793

- info@kankengineers.com

- Banashankari 6th Stage, Bangalore 560062

©2023. kanaje Engineers. All Rights Reserved.

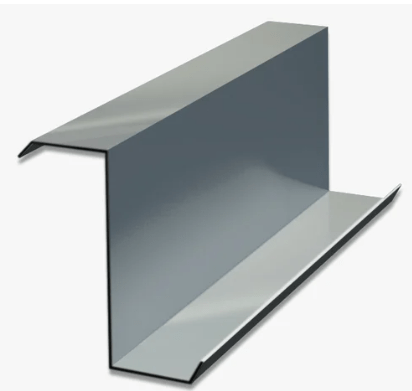

C purlins, as the name implies, are formed as in the C alphabet, which is primarily used to support walls and floors. C section purlins or cee section purlins are built to shape a building shell structure’s walls and floor joists, making them also suitable for supporting the beams required for flooring

The maximum distance between purlins is five (5) feet on center. If your building site is in a region that is prone to heavy snow loads or high winds, then we may place your purlins closer together for added strength

Z and C purlins have different angles. The C purlin has an angle of 90 degrees, and the Z purlin has an angle that is less than 90 degrees. Due to this, Z purlins are more flexible than C purlins and can be used for a variety of purposes.

Full range of thicknesses available for both Z and C purlins are:

1.2mm 1.3mm

1.4mm 1.5mm

1.6mm 1.8mm

2.0mm 2.5mm

available

©2023. kanaje Engineers. All Rights Reserved.